Flöde Leads the Way: Sustainability as Strategy – Not an Add-On

There’s a lot happening at Flöde, an innovative initiative within sustainable textiles that is currently experiencing rapid growth. With a clear vision to transform the linear textile industry, Flöde is developing scalable methods for value-added reuse while spreading knowledge and building new production capacity in both Sweden and Europe. Having recently opened their new manufacturing hub in Greece and the team is now preparing to launch their consultancy services, a step toward becoming a strategic partner for brands looking to take real action toward a more circular business model. We asked the team behind Flöde a few questions to learn more about their journey, driving forces, future plans, and why they believe sustainability isn’t an add-on, but a mindset.

Tell us a bit about Flöde — how would you describe your operations and your vision?

We develop methods and offer services around scalable and value-added reuse to accelerate the sustainable transformation of the textile industry.

Flöde is an innovative and forward-thinking concept within textile reuse. Our operations are based on the EU’s climate goals and upcoming legislation, with the ambition to reduce new production and unsustainable business models while increasing awareness and raising knowledge levels around textile sustainability. Flöde aims to reduce resource consumption and waste generation while maximizing the efficient use and reuse of existing materials. Our goal is to extend the life of textile products and eliminate the need for producing virgin fibers through our consulting and manufacturing services for scalable reuse, which we’re launching this fall. We want to prove that it is indeed possible to be both sustainable and profitable.

Flöde stands on three pillars:

Innovation through in-house R&D, where we develop methods for product development and scalable upcycling manufacturing models.

Knowledge distribution around the sustainable transition in the textile industry, upcoming legal requirements, and our own methods. The knowledge generated through our innovation work is shared through our consulting services and product development offerings for garment materials.

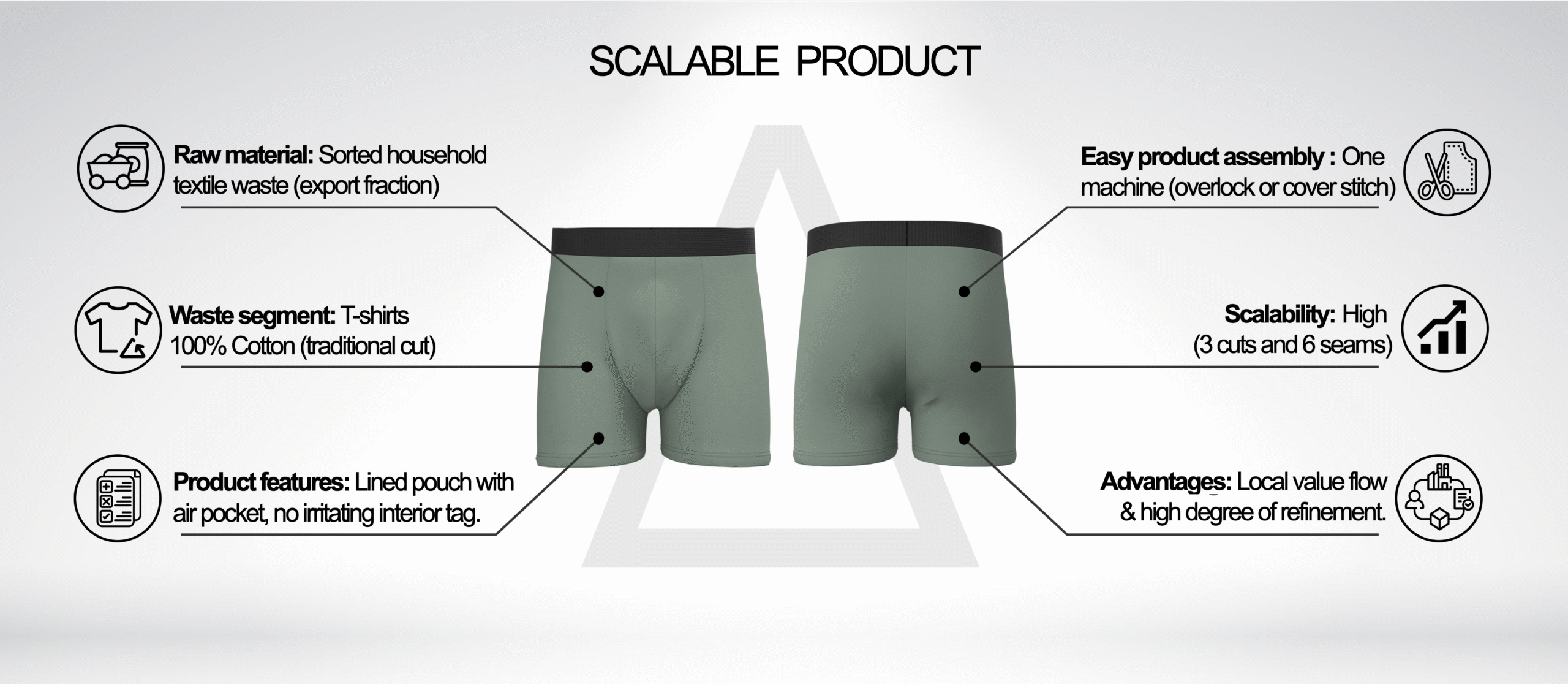

Manufacturing at NNML [No New Material Lab]. Our labs in Stockholm and Thessaloniki (Greece) offer prototyping, updates and reworking of surplus stock, as well as serial production. The lab is a place where we aim to gather all flows. Here we test and develop our production models and methods for scalable products designed to be cut from existing garment materials.

Which focus areas or initiatives are you currently working on?

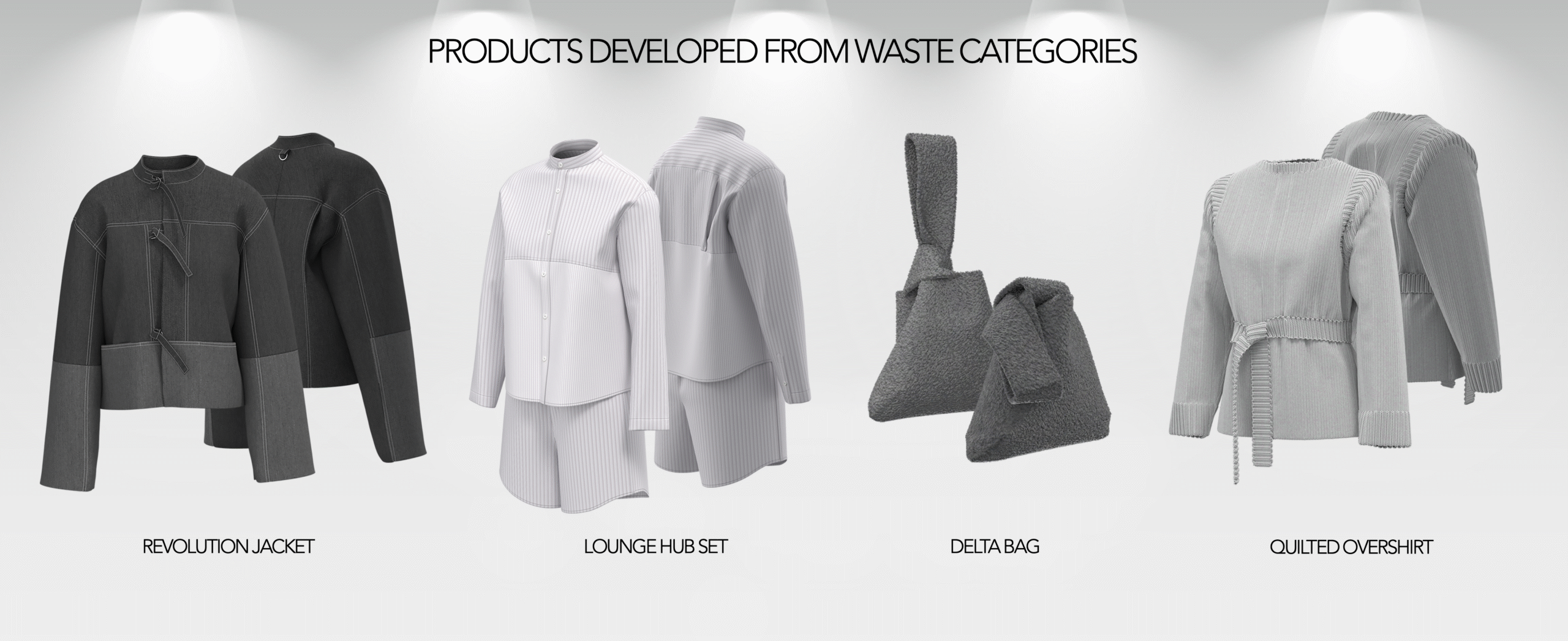

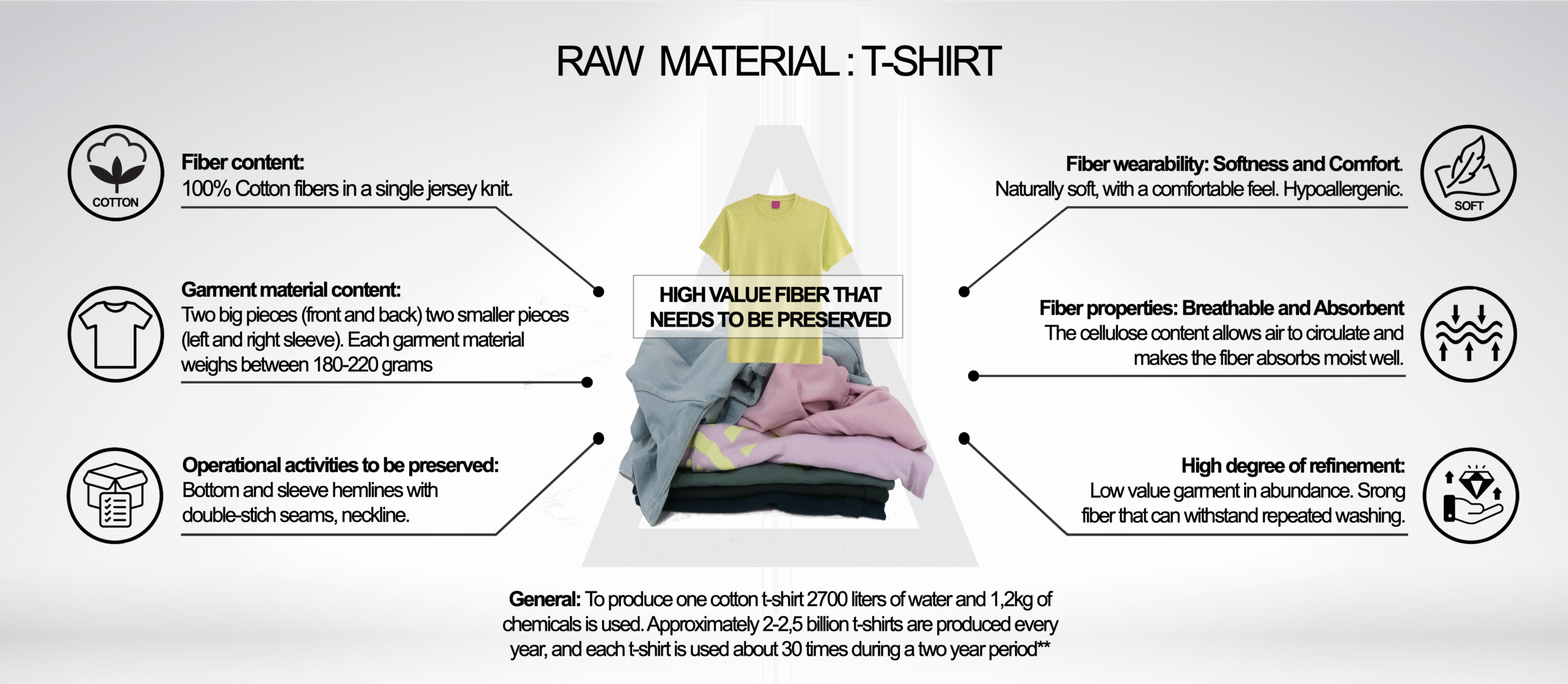

Right now, we’re focused on continued product development using our own model to produce more strong examples of garments designed for production from existing garment materials. We’re developing complete product proposals along with sorting and production matrices. Beyond product development, we are investing heavily in knowledge distribution, giving talks at educational institutions to raise awareness and understanding of textile sustainability.

We’ve also just opened our manufacturing hub in Thessaloniki, northern Greece, which allows us to offer European production to brands either lacking manufacturing partners or seeking to bring production closer to Sweden.

What has been the driving force behind your sustainability efforts?

Flöde’s vision is No More New a world where every textile fiber gets a new beginning through value-added reuse in local value flows. Our passion stems from within, but a key catalyst was gaining deeper insight into the limitations of fiber recycling. Recycling textile waste is complex and today brings a maximum environmental benefit of about 10%, as the recycling process often requires the same amount of energy and chemicals as producing virgin materials. In contrast, the benefits of upcycling are many, and the environmental impact is much more positive but it demands commitment and broad expertise to understand the processes involved in scalable reuse. This complexity can be a barrier for businesses operating within the linear value chain.

That’s why Flöde wants to offer services that help both existing and new businesses advance their sustainability work and accelerate the shift to a circular textile industry. We firmly believe that sustainability and profitability can, and must, go hand in hand.

How is sustainability integrated into your products and processes?

Flöde represents the sustainable businesses of the future, ones that measure more than just financial value and prioritize people and products. We don’t see sustainability as something to be added; it’s a mindset. For us, it’s absurd to create products solely for the purpose of generating profit. Instead, we want to establish a new narrative around consumption and greater accountability among producers.

In a sustainable future, we envision higher quality of life in a society where knowledge and creativity drive the circular economy forward, where textile reuse is seamlessly integrated into everyday life, and where products serve a clear purpose and hold value once again.

What role does a physical space play in your sustainability strategy?

Having a physical space is central to us, not only to create stability for the team’s work, but also to enable our exploratory lab activities. To move forward with circular transformation, partnerships and cross-industry collaboration are essential. That’s why transparency and accessibility among those pushing for change are so important, and a physical space helps enable that. It’s also vital for our mentorship program for young creators.

What challenges do you see in the industry when it comes to working more sustainably?

The existing business model, the linear value chain itself, and the lack of knowledge it has perpetuated. It’s full of systems and work methods that make change difficult, add to that what we see as an unhealthy obsession with capital, misinformation, and an overreliance on recycling. The list is long. Swedish policy doesn’t exactly make it easier, either. Sandra Roos, Head of Sustainability at Kappahl, highlights this well in an op-ed published here in Dagens Industri earlier this May.

Is there a particular initiative or project you’re especially proud of?

We’re generally not great at bragging, but we’re quite proud of our complete product proposals: the Only Pant Boxer, a men’s boxer short, and the Lounge Hub Set, a cotton pajama. Both demonstrate scalability, material value increase, and profitability, despite domestic remanufacturing.

What are your future goals in the sustainability space?

Our big vision is for Flöde to become one of Europe’s top upcycling factories by 2030. Along the way, we’ll continue developing scalable products, local material flows, and manufacturing models for textile reuse and upcycling. As soon as this fall, we hope to begin working with Swedish brands through our consulting services and share our knowledge around product development for garment materials.

We encourage all forward-thinking brands to reach out and explore the possibility of reworking or updating their surplus stock, something we believe will become a necessity when producer responsibility regulations come into force. We already have several great examples of completed projects where we’ve helped brands activate dormant inventory through simple updates, creating new value without using new materials!